- Contact us

- |

- About us

- |

- |

-

- Personal information

- Organization

- Quotes

- Address book

- Login

- Don't have an account? Sign-up

Conductive O-profiles

- Home

- EMI shielding gaskets solutions

- EMI/IP gasket

- Conductive O-profiles

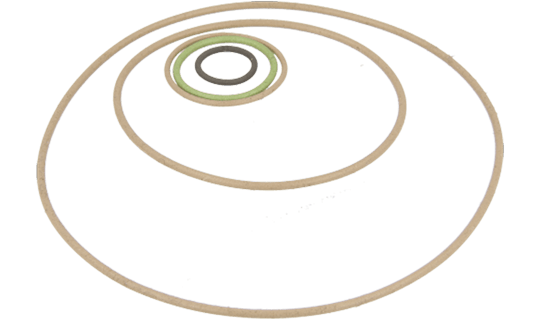

Several types of O-profiles have been developed for different applications, each with its own advantages. O-profiles were originally designed for high-performance shielding, mainly for military applications. They are used when environmental sealing and EMI screening are required, and where there is little space.

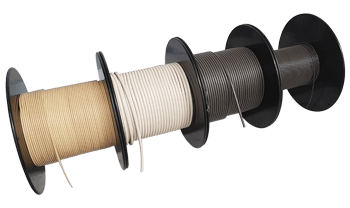

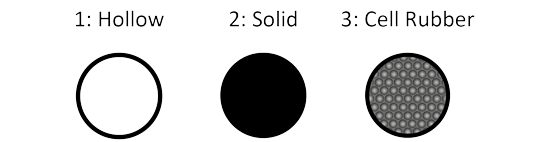

Three kinds of extrusion types are available: 1: hollow, 2: solid, 3: Cell Rubber. These extrusion cores can be covered with metallized fabric foil or they can be made out of conductive rubber. For optimal shielding performance a compression of 5-10 % is recommended for solid elastomers and 10-50 % for hollow extrusions and sponge rubbers.

Benefits

- Easy to fit into grooves

- Deflection up to 50%

- Low closure force

Options (on request)

- Cut into accurate lengths or endless O-rings

- Drop-out prevention fixtures

- UL94V-0 flame-retardant version

- High temperature-resistant Silicone core (up to 220 °C)

- Fluorosilicone (silver aluminium, silver copper, nickel, nickel graphite) for applications with chemicals

Compression

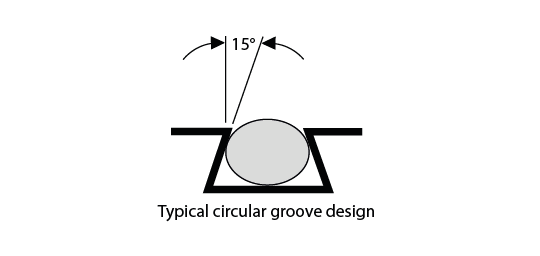

Solid elastomers cannot be compressed much. They are easily deformed but the volume does not change as would be the case with sponge elastomer (PVC, EPDM, Neoprene) so that allowance for material flow must be considered in the groove design.

The figure below shows a groove design. This is a mechanically retain circular cross-section gaskets by side friction.

Material options

| Type | Code | Core | Cover |

|---|---|---|---|

| 7900-x-11-x | 11 | Neoprene | Amucor foil |

| 7900-x-12-x | 12 | Neoprene | Conductive fabric |

| 7900-x-21-x | 21 | Silicone | Amucor foil |

| 7900-x-22-x | 22 | Silicone | Conductive fabric |

| 7900-x-41-x | 41 | EPDM | Amucor foil |

| 7900-x-42-x | 42 | EPDM | Conductive fabric |

| 7900-x-53-x | 53 | Silvered particles filled silicone rubber | - |

| 7900-x-54-x | 54 | Nickel filled silicone rubber | - |

| 7900-x-55-x | 55 | Graphite filled silicone | - |

| X needs to be replaced for extrusion type & dimensions | |||

Extrusion types

Special materials (on request)

These O-profiles are also available in special materials for special applications for example applications with chemicals. Below is a list of special materials. For availability and delivery please contact us.

- Silicone Carbon

- Fluorosilicone Nickel Graphite

- Silicone Nickel Graphite Flame Retardant

- Silicone Silver Aluminium

- Fluorosilicone Silver Aluminium

- Fluorosilicone Nickel

- Silver Plated Nickel

- Silver Glass

Shielding performance and technical details table (dB)

Shielding effectiveness depends on the surface, the shape of gaskets and the materials used.

| Conductive Filler | Conductive fabric | Amucor | Graphite | Nickel Graphite | Silver Aluminum |

|---|---|---|---|---|---|

| Standard | |||||

| Frequency | Shielding Performance STD 285 /MIL-DTL 83528C (dB) | ||||

| 10 MHz | N/A | N/A | 30 | 115 | 111 |

| 100 MHz | 60 | 65 | 65 | 121 | 120 |

| 400 MHz | 98 | 110 | 60 | 119 | 120 |

| 1 GHz | 94 | 108 | N/A | 122 | 121 |

| 2 GHz | 91 | 105 | 40 | 122 | 119 |

| 6 GHz | 90 | 102 | N/A | 115 | 115 |

| 10 GHz | 90 | 100 | 30 | 114 | 112 |

| 18 GHz | N/A | N/A | N/A | 106 | 105 |

| OperatingTemp | - | - | +160 | +160 | +160 |

| Range (°C) | - | - | -50 | -55 | -55 |

| Colour | Grey | Silver | Black | Dark Grey | Beige |

| Shore Hardness (A +/-5) ASTM D2240 | - | - | 60 | 60 | 65 |

| Volume Resistivity (ohms/cm) ASTM D991 | - | - | 2.2 | 0.04 | 0.008 |

| Specific Gravity (+/- 0.25) | - | - | 2.0 | 2.0 | 2.0 |

Standard extrusions (other sizes on request)

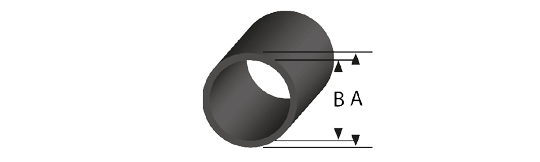

Type 1: Hollow

| Hollow | ||

|---|---|---|

| Size | Outside A (mm) | Inside B (mm) |

| 0.9 X 0.3 | 0.9 | 0.3 |

| 1.2 X 0.5 | 1.2 | 0.5 |

| 1.6 X 0.5 | 1.6 | 0.5 |

| 1.8 X 0.5 | 1.8 | 0.5 |

| 1.9 X 0.7 | 1.9 | 0.7 |

| 2.0 X 0.5 | 2.0 | 0.5 |

| 2.0 X 0.8 | 2.0 | 0.8 |

| 2.4 X 0.8 | 2.4 | 0.8 |

| 2.4 X 1.0 | 2.4 | 1.0 |

| 2.6 X 1.5 | 2.6 | 1.5 |

| 3.0 X 0.5 | 3.0 | 0.5 |

| 3.0 X 0.8 | 3.0 | 0.8 |

| 3.0 X 1.0 | 3.0 | 1.0 |

| 3.0 X 1.6 | 3.0 | 1.6 |

| 3.2 X 0.8 | 3.2 | 0.8 |

| 3.2 X 1.1 | 3.2 | 1.1 |

| 3.2 X 1.5 | 3.2 | 1.5 |

| 3.5 X 0.8 | 3.5 | 0.8 |

| 3.5 X 1.6 | 3.5 | 1.6 |

| 3.6 X 1.5 | 3.6 | 1.5 |

| 4.0 X 1.1 | 4.0 | 1.1 |

| 4.0 X 1.3 | 4.0 | 1.3 |

| 4.0 X 1.6 | 4.0 | 1.6 |

| 4.0 X 2.0 | 4.0 | 2.0 |

| 4.1 X 2.0 | 4.1 | 2.0 |

| 4.5 X 1.6 | 4.5 | 1.6 |

| 4.8 X 2.4 | 4.8 | 2.4 |

| 5.0 X 1.6 | 5.0 | 1.6 |

| 5.0 X 3.0 | 5.0 | 3.0 |

| 5.5 X 1.6 | 5.5 | 1.6 |

| 5.5 X 3.2 | 5.5 | 3.2 |

| 6.0 X 1.6 | 6.0 | 1.6 |

| 6.0 X 3.2 | 6.0 | 3.2 |

| 6.0 X 4.0 | 6.0 | 4.0 |

| 6.4 X 1.6 | 6.4 | 1.6 |

| 6.4 X 3.2 | 6.4 | 3.2 |

| 8.0 X 5.0 | 8.0 | 5.0 |

| 8.0 X 6.0 | 8.0 | 6.0 |

| 9.0 X 6.4 | 9.0 | 6.4 |

| 9.5 X 6.4 | 9.5 | 6.4 |

| 10.0 X 7.0 | 10.0 | 7.0 |

| 10.0 X 8.0 | 10.0 | 8.0 |

| 12.0 X 8.0 | 12.0 | 8.0 |

| 15.0 X 12.0 | 15.0 | 12.0 |

| 16.0 X 12.0 | 16.0 | 12.0 |

| 20.0 X 16.0 | 20.0 | 16.0 |

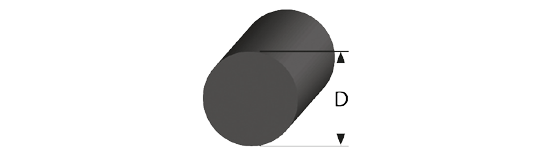

Type 2: Solid

| Solid | Suggested groove dimensions | ||

|---|---|---|---|

| Size | Diameter (mm) | Depth +/- 0.005 |

Width 97% max groove fill |

| 1.0 | 1.0 | 0.74 | 1.60 |

| 1.2 | 1.2 | 0.94 | 1.70 |

| 1.4 | 1.4 | 1.04 | 1.83 |

| 1.6 | 1.6 | 1.24 | 2.01 |

| 1.8 | 1.8 | 1.42 | 2.18 |

| 2.0 | 2.0 | 1.63 | 2.39 |

| 2.4 | 2.4 | 1.93 | 2.72 |

| 2.6 | 2.6 | 2.13 | 2.97 |

| 2.8 | 2.8 | 2.34 | 3.17 |

| 3.0 | 3.0 | 2.59 | 3.33 |

| 3.2 | 3.2 | 2.71 | 3.53 |

| 3.5 | 3.5 | 2.90 | 3.86 |

| 4.0 | 4.0 | 3.28 | 4.34 |

| 4.5 | 4.5 | 3.54 | 4.63 |

| 4.8 | 4.8 | 3.91 | 5.08 |

| 5.0 | 5.0 | 4.06 | 5.26 |

| 5.4 | 5.4 | 4.50 | 5.94 |

| 5.5 | 5.5 | 4.55 | 6.04 |

| 6.0 | 6.0 | 4.90 | 6.45 |

| 6.4 | 6.4 | 5.15 | 6.75 |

| 7.0 | 7.0 | 5.74 | 7.39 |

| 7.5 | 7.5 | 6.04 | 7.85 |

| 8.0 | 8.0 | ||

| 8.5 | 8.5 | ||

| 9.0 | 9.0 | ||

| 9.5 | 9.5 | ||

| 10.0 | 10.0 | ||

| 11.0 | 11.0 | ||

| 12.0 | 12.0 | ||

| 15.0 | 15.0 | ||

| 18.0 | 18.0 | ||

| 20.0 | 20.0 | ||

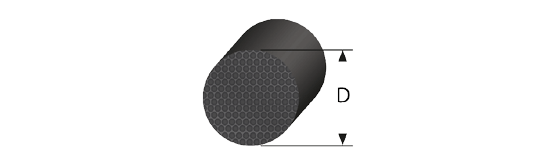

Type 3: Cell rubber

| Cell Rubber | |

|---|---|

| Size | Diameter (mm) |

| 2.1 | 2.1 |

| 3.0 | 3.0 |

| 3.5 | 3.5 |

| 4.0 | 4.0 |

| 4.5 | 4.5 |

| 5.0 | 5.0 |

| 5.5 | 5.5 |

| 6.0 | 6.0 |

| 6.5 | 6.5 |

| 7.0 | 7.0 |

| 7.5 | 7.5 |

| 8.0 | 8.0 |

| 8.5 | 8.5 |

| 9.0 | 9.0 |

| 9.5 | 9.5 |

| 10.0 | 10.0 |

| 11.0 | 11.0 |

| 12.0 | 12.0 |

| 15.0 | 15.0 |

| 18.0 | 18.0 |

| 20.0 | 20.0 |

| 22.0 | 22.0 |

| 25.0 | 25.0 |

7910 Conductive jointed O-rings

We also supply Conductive jointed O-rings. The 7910 series are practically the same as the 7900 series O-Profiles, however, this is a turnkey closed O-ring. They are used where environmental and EMI screening is required but were little space is available.

For more information about check out our Conductive rubber O-rings page.